Features

- Compatible with precut tape, the system eliminates cutting and rewinding steps.

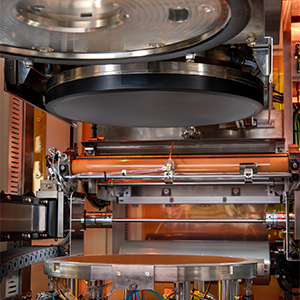

- Designed to cope with high-strength polyimide (PI) film. A mechanical mechanism separates and fixes the film onto the platform, and uniform heating, which enables a smooth, wrinkle-free lamination of the film onto the frame.

Advantages

- The film can be uniformly preheated before mounting.

- The pressure can be controlled during mounting.

- A drawer-type mechanism for simultaneous placement of dual cassettes.

- Scan RFID of tape

- Scan 2D Code of frame

- Scan 2D Code of cassette

- SECS/GEM

Operation

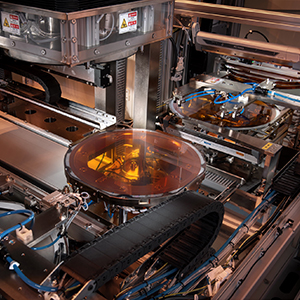

- ➠Empty metal frames are manually loaded into the frame stacker, and empty cassettes into the cassette module, with film installation completed thereafter.

- ➠The arm takes the frame to the mounting table as a precut tape is torn off and fixed on the film platform.

- ➠The film platform moves downward to press onto the mounting table, carrying out the mounting process.

- ➠The arm removes the frame and transfers it to the cassette (unloading).

Specifications

| Dimension | 2130 × 2400 × 2400 mm ( W×D×H ) |

|---|---|

| Weight | 2560 kg |

| AC Power | 220V Single-Phase, 60Hz |

| Air Supply | Air Pressure 7 kgf/cm2 Air Tube Diameter Ø12mm |

Object wafer and ring

| Wafer Size | – |

|---|---|

| Ring Size | 10-inch |

| Tape Size | Width 380mm Ø325mm Precut Tape |

Features

Automatic

Fully automatic continuous production.

Rapid Production

No need for tape cutting and rewinding time.

Parameters Controlled

Mounting parameters are controlled to ensure stable quality.

Clean Air Supply

Equipped with dual 22.5 x 46 inches HEPA air supply units.

Production Traceability

The barcodes of new film rolls, metal frames, and cassettes are read and uploaded to the host system.

Uniform Heating

The film can be uniformly preheated before mounting.

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.