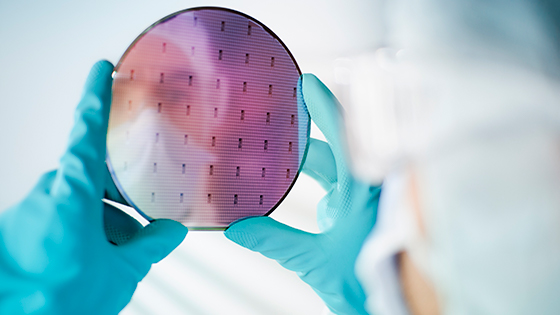

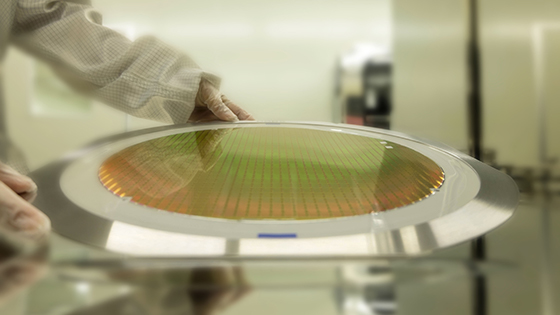

N-TEC started as a mechanical equipment importer/exporter to introduce advanced equipment to Taiwan from Europe and America and sell made-in-Taiwan equipment to more than 20 countries around the world. Since 2005 N-TEC has been dedicated in the innovative development and production of LED equipment. We have an extended line of wafer breakers ranging from automatic to semiautomatic, digital to analog, and from 2”, 4”, 6” to 12” of today. We know what clients want for the manufacturing process and work together with them to develop software and hardware solutions customized for them. Our professional line of service has won the recognition of domestic and international big names.

History of Development

2024

- Strategic alliance with international manufacturers of 8-inch full auto wafer breaker and laser cutters, targeting IDM customers.

2023

- Develop full-auto film laminator and foil detach tool for Mini LED for major european and american international manufacturers.

2022

- Develop full-auto wafer mounter and fully automatic wafer laminator for both square and round devices and provide them to semiconductor manufacturers.

2021

- Started to provide UV machine LED to semiconductor packaging factory.

2019

- Automatic 12-inch wafer mounter was developed and sell it to the clients successfully.

2018

- Provide automatic 6”, 8” wafer washer to international major factories.

2017

- The 12” wafer breaker dedicated for semiconductor production (with built-in wafer retaping and expanding, mounting and removing) was developed.

2016

- A series of automatic 6” and 8” LED processing equipment was developed including automatic Laminator, automatic Mounter, automatic wafer Expander and automatic Retaper, and the series was highly recognized by major international manufacturers.

2015

- The R&D work started for 8” and 12” LED wafer equipment.

2013

- The production facility was expended from 1300m2 to 3560m2.

- The proprietary tape Grinder, Lapping machine and Polishing machine were developed; no more waxing or washing with organic solvent is required for better environment.

2010

- Sales increased 10-fold.

- Breaker market expended to the US.

- The R&D work started for 6” LED wafer equipment.

2009

- N-TEC covered more than 70% of Taiwan and Chinese markets for LED wafer Breakers.

- The production facility was doubled from 650m2 to 1300m2.

2007

- The first LED wafer breaker was developed.

Our future will be dedicated to the development of fully automatic equipment line, including Breaker, Laminator, Mounter, wafer Expander and Retaper for the application in the 12” semiconductor wafer packaging.

Core Concepts

N-TEC starts from new product development to mass production. We provide a wide diversity of products in order to increase the profitability. N-TEC is also working hard to fulfill our corporate social responsibilities and make positive influence to the general society as an effort to improve our corporate values.

Business Strategies

N-TEC develops products that meet clients’ demands by keeping a track on what clients want and the pulses of industrial development. We are moving toward the development of automation and improvement of equipment quality and cost-performance ratio to meet clients’ requirements. “Customers first” and “Grow with clients” are N-TEC’s mottos. We aim to improve our service quality continuously and provide professional and complete service for worldwide partners.

Competitive Advantages

- The center of our competitive advantages is a professional group of engineers who are experienced, highly qualified, and dedicated to what they do best in their positions.

- We infuse leading technology and innovative concepts in the equipment produced to show our strong ability of customization.

- We lead in manufacturing. The strict quality control along the production process facilitates the steady quality of equipment.

- Intellectual property right is a key to our business as we have accumulated more than 100 patents.

- Ask any of our clients and they will tell N-TEC is a trustworthy partner in business. We have been working with more than 100 clients for more than a decade and now they are our partners.

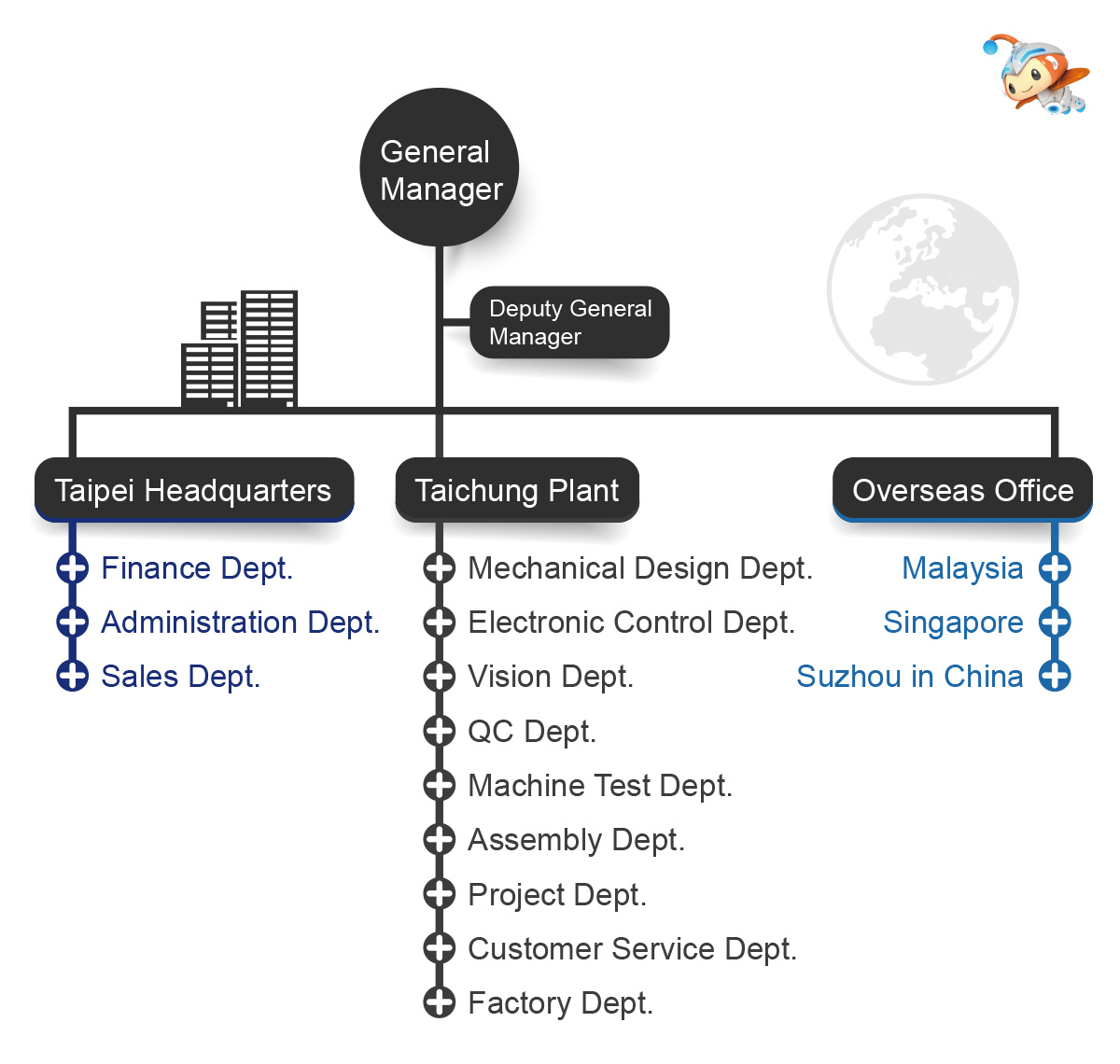

Company organization