Feature

- Film cutting by melting

- Easy to operate

Advantages

- Easy film replacement

- High tension on the film mounting side

- Film cutting by melting without damaging flat ring

- Serves as manual film remover as well

- Repeated wafer rolling for increased adhesion

- User-friendly operation interface

- No residual bubble

Operation

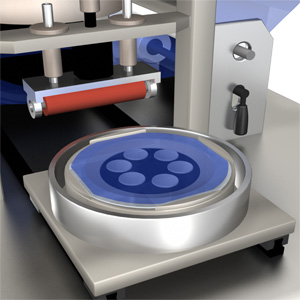

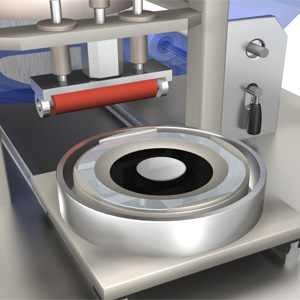

Place a 6” flat ring on the mounter’s carrier and then a 2” or 4” wafer on the suction wafer seat. Activate flat ring suction and wafer suction. The carrier moves to film attaching position. The film is lowered and cut by melting automatically onto the flat ring. The carrier moves out in front of the placement area where a roller makes the film adhere to the wafer. The adhesion pressure is adjustable depending on the type and thickness of wafer. The film tension is adjustable to meet the client’s process need.

The operator removes the work piece after adhesion.

Specifications

| Dimensions | 1000 mm × 1041 mm × 1880 mm ( W×D×H ) |

|---|---|

| Weight | 500 kg |

| AC power | 1 Ø 220 V ∕ 10 A |

| Air supply | 6~8 Kgf ∕ cm2 (10 ØTube) |

Object Wafer and Ring

| Wafer size | 2″~ 4″ |

|---|---|

| Chip size | None |

| Laser cut depth | None |

| Flat ring size | 6″ Flat Ring ( inner Ø 194 mm; outer 228 mm; t= 1.0 ~ 1.3 mm ) |

Features

Flat Ring Placement Detection

Patented Mechanism of Wafer Suction by Area

Wafer suction by area to reduce wafer warping and improve production yield of film attachment

Multiple Options for Wafer Suction

Independent Flat Ring Film Attachment Possible

Quick Replacement

Quick replacement of membrane and waste material reels

Adjustable Adhesion Pressure Based on Thickness

Full ∕ Broken Wafer Mounted

Automatic 2”, 4” full ∕ broken wafer mounted

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.