Feature

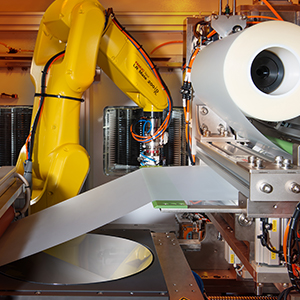

- Six-axis multi-angle cutting

- Supports RFID

- Overhead hoist transport (OHT) system

Advantages

- Film lamination tension control

- Alignment: CCD graphic recognition alignment

- FFU HEPA high efficiency air filtration for Class 1000 cleanroom environment

- The machine can be operated continuously without stopping while the operator performs FOUP changes

- Dual-touchscreen interface

Operation

Step 1: Place the 12″ FOUP on the load port, install film in the designated position and start operation.

Step 2: Open the cover of the load port and complete the mapping scan.

Use the robot to remove the first wafer from the cassette and place it on the alignment table to initiate the aligned calibration, and to remove a second wafer and place it on the temporary fork.

Step 3: Use the robot to pick up the calibrated wafer and place it on the suction platform. Raise the suction platform to the suction position. Meanwhile, transfer the second wafer to the alignment table by the buffer transfer mechanism for aligned calibration. Use the robot quick change device, place the fork in the fork position and go to the cutter preheating zone to pick up the cutter.

Step 4: Use the roller to apply the film to the wafer.

Step 5: Use the robot to cut the wafer edge with a cutter and move the robot out of the suction zone after cutting. Return the cutter to the preheating zone using the robot quick-change device and pick up the fork from the fork placement bay.

Lower the suction platform to the in-out handshaking position.

Step 6: Use the robot to return the 1st wafers to the FOUP.

Step 7: Use the robot to remove a third wafer from the cassette and place it on the temporary fork.

Keep repeating steps 3 to 7.

Cutting edge cleaning: Use the robot to take the cutter from the preheating zone to the cutting-edge cleaning position and return it to the cutter preheating zone after finishing the cleaning.

Specifications

| Dimensions | 1930 × 2230 × 2400 mm ( L×W×H ) exclude from tricolored light |

|---|---|

| Weight | 2000 kg |

| AC Power | 380V(Three-phase 5-wire;Line to neutral: 220V) |

| Air Source | Air Pressure 0.7~0.8 MPa Air Tube Diameter Ø12mm |

Object Wafer and Ring

| Wafer size | 12inch |

|---|---|

| Chip size | – |

| Frame size | – |

| Tape size | Width 330mm × Length 100M |

Features

Cutter Preheating

Film cutting edge: preheating up to 200 degrees

Cutter Clean

Clean the cutting edge

Platform Heating

Suction platform: Carrier temperature capped at 110 degrees

Teflon

Wafer suction platform coated with anti-static Teflon

Roller Heating

Suction the film to the rollers: roller temperature capped at 110 degrees, roller lower pressure adjustment

Quick Change of Film

Pneumatic roll film fixing, quick change of film

Static Elimination

Static elimination device

SEMI

SECS / GEM / E84

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.