Feature

- Control of the mounting for different tensions

- Multi-position And Multi-angle Labeling

- SECS / GEM

Advantages

- In automatic mode, the machine can be stopped at any time for replenishment of the frames

- Minimize tape consumption and cutting spacing

- The frame tape mounting and labeling functions support both dual-function and single-function automatic operations

Operation

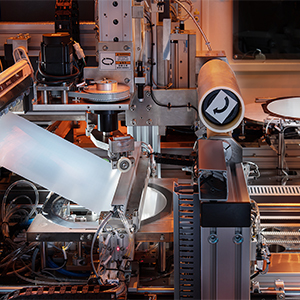

Manually place the frames into the stacking mechanism, load empty cassettes into the cassette module, and install the tape.

- ➠The arm will transfer a frame to the mounting platform, and the tension adjustment mechanism will pull out new tape.

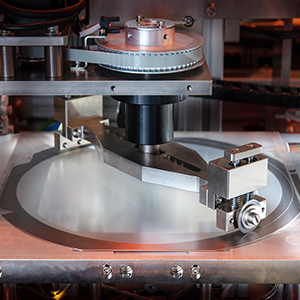

- ➠The tape will be mounted through a rolling process, and a cutter will descend to cut a circle and separate the excess of tape.

- ➠The arm will transfer the frames with tape to the labeling platform for labeling.

- ➠The arm will push the labeled frame to the cassettes for unloading.

Specifications

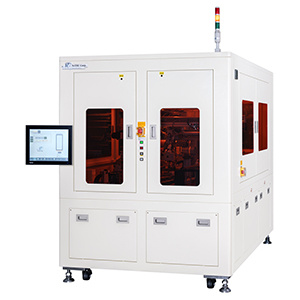

| Dimensions | 1600 × 2200 × 2380 mm ( W×D×H ) |

|---|---|

| Weight | 2000 kg |

| AC Power | 220V Three phase, 50/60Hz |

| Air Source | Air Pressure 7kgf/cm2 Air Tube Diameter Ø12mm |

| Vacuum Supply | Air Tube Diameter Ø12mm |

Object Wafer and Ring

| Wafer Size | – |

|---|---|

| Ring Size | 8-inch |

| Tape Size | W: 300mm × L: 100 M |

Features

Automatic

Fully automatic rapid production.

Reduce Cost

Minimize tape consumption and cutting spacing.

Film Mounting Tension Control

Control different tensions to ensure mounting stability.

Replenish Frames in Automatic Mode

Multi-Position and Multi-Angle Labeling

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.