Feature

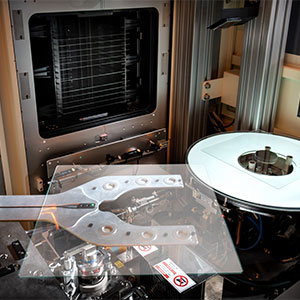

- The machine can be operated continuously without stopping, control of the laminating for different tensions.

Advantages

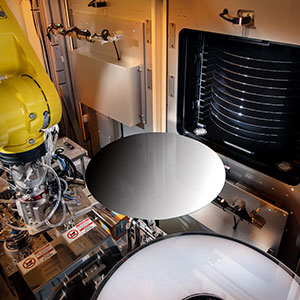

- By adopting the visual alignment method, both round and square wafers can be processed in the same production process

- FFU HEPA high efficiency air filtration meeting the requirements for Class 1000 cleanrooms environment

- Dual-touchscreen interface

- Loading and unloading in a AGV unmanned transport system

Operation

Fully Automatic

Specifications

| Dimensions | 1850 × 2003 × 2500 mm (W×D×H) |

|---|---|

| Weight | 1740 kg |

| AC Power | single-phase 220V 60HZ |

| Air Source | 6kgf ∕ cm2 |

Object Wafer and Ring

| Wafer size | 8-inch、12-inch、square 212 × 216 mm |

|---|---|

| Tape size | 8-inch wafer : 230 mm × 100 meter 12-inch wafer : 330 mm × 100 meter square panel : 330 mm × 100 meter |

Features

AGV

Loading and unloading in an unmanned transport system.

Film laminating roller heating

Maximum temperature : 110 degrees.

Cutter/carrier heating

Cutter heating, maximum temperature: 200 degrees.

Wafer carrier temperature control, maximum temperature: 110 degrees.

Cutter Clean

Clean the cutting edge.

Wafer ID recognition

OCR and reading function.

Static Elimination

Static elimination device.

Signal Feedback

Digitization of each monitoring meter head and signal feedback.

SEMI

SECS / GEM / E84

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.