Feature

- Luminous exposure can be adjusted according to the change of recipes

- Bernoulli fork, supporting wafers with the warpage of less than 7mm

- Tape visual defect inspection, peeling off UV tape

- Precut tape with low tension mounting mechanism

Advantages

- Illumination monitoring

- Temperature monitoring of the illumination room

- Multi-screen touch interface

- FFU HEPA high efficiency air filtration meeting the requirements for Class 1000 Cleanroom

- Loading and unloading in a AGV unmanned transport system

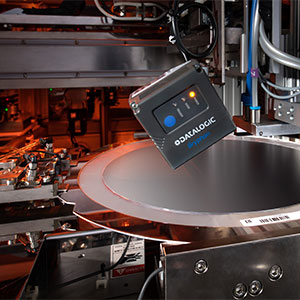

- Tape RFID identification system

- Handheld barcode scanner setting

Operation

Fully Automatic

Specifications

| Dimensions | 3323 × 2930 × 2573 mm (W×D×H) |

|---|---|

| Weight | 4600 kg |

| AC Power | single-phase 220V 60HZ |

| Air Source | 6kgf ∕ cm2 |

Object Wafer and Ring

| Wafer size | 8-inch、12-inch、square 212 × 216 mm |

|---|---|

| Ring Size | outer diameter Ø296, inside diameter 250, width 276,t=1.2 mm outer diameter Ø400, inside diameter 350, width 380,t=1.5 mm |

| Tape size | 8-inch Precut = 290 mm, normal =300 mm 12-inch Precut = 390 mm, normal = 400 mm |

Features

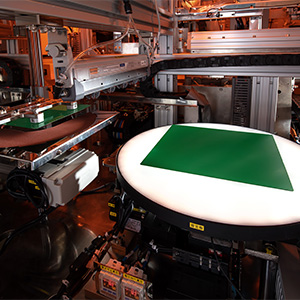

The precut tape mounting mechanism

Adopted to achieve low tension mounting.

Double-slot judgment

The number of wafers in the cassette, position, stacked wafers, double-slot detection.

AGV

Loading and unloading in an unmanned transport system.

Temperature monitoring

Illuminance meter monitoring, temperature monitoring.

Meter signal feedback

Digitization of monitoring meter, signal feedback.

Label Sticker

60 x 10 and 60 x 12 mm label

Supporting static elimination

Static Eliminator

SEMI

SECS-GEM communication with E84 interface

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.