Feature

- SECS / GEM functions

- Load port support available

- OCR Wafer ID recognition with separate front and back-side reading

- Special alignment modules (notch, V-shape, drawing and special drawing positioning)

- 8″/ 12″ wafers switch with software, without the need to change conversion kit

- Suitable for different types of film operations. (e.g., UV Tape, non-UV Tape)

- Quick change for different widths of film without mechanism adjustment

- Powerful functions for detecting film mounting, film shortage and film breakage

- Low film detection, out of material indication, remote real-time monitoring

Advantages

- In automatic mode, the machine can be stopped at any time for replenishment of the frames and film

- User-friendly design with adjustable interface for standing and sitting positions

- Double screen for easy operation

- The mechanism can handle entire stacks of frames depending on the process requirements

- Frame warp detection

- Quick film change and waste roller replacement

- Heated mounting platform with recipe switching as required by the process to provide optimum mounting conditions

- Film mounting roller pressure adjustable, cassette barcode auto reading

Operation

Place frames → Place FOSB → Place cassettes → Take glass pieces by arm → Align wafers → Take the frame by arm → Put glass pieces and frames on the platform → Move the platform to the mounting position → Film mounting roller moves downwards → Move the platform slowly → Film mounting roller rises and leaves (mounting completed) → Cut film → Carry out film slitting → Platform moves down → Leave the film mounting section → Take the finished piece by arm and turn it over → Pushing cylinder feeds the frame into the cassette.

Specifications

| Dimensions | 2070 × 3000 × 2030 mm ( L×W×H ) |

|---|---|

| Weight | 3000 kg |

| AC Power Supply | Operating Voltage: 220V ∕ 50-60 Hz 3 Ø Volt.(V) Machine Switch (NFB): 20A |

| Air Source | 85-114 psi ∕ 3 ft3/min @ 12mm diameter -600 mmHg (-80 kpa) ∕ 0.6 ft3/min @ 12mm diameter |

Object Wafer and Ring

| Wafer size | 8″ / 12″ |

|---|---|

| Chip size | – |

| Frame size | 12″ |

| Tape size | Width 400-430mm × Length 100m for plastic rings |

Features

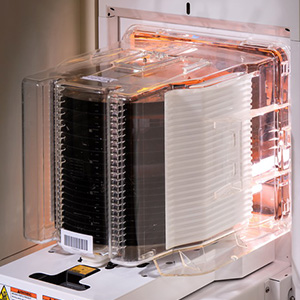

Load Port

FOUP mapping

Cassette

Double cassette design

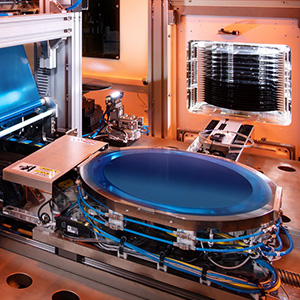

Mounting Platform

Contains heating function

Fully Automatic Rapid Production

Cassette Barcode Reading

Wafer Barcode Reading

Quick Film Replacement

Quick film change and waste roller replacement

Film Detection

Film mounting / shortage detection

Cutter

Switch to round cutter

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.