Feature

- The low tension EPC system performs the tension adjustment

- It is equipped with a 12-megapixel image recognition system for precise alignment and correction

- Fully automated loading / Unloading and transfer system

- All material handling shafts adopt an air-shaft design

Patent

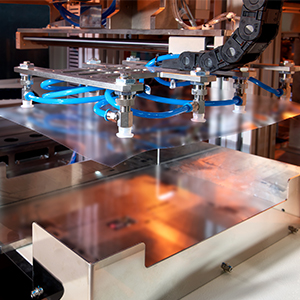

Film LaminatingRelease Film Peeling

Advantages

- HEPA high efficiency air filtration for Class 1000 cleanroom environment

- The automatic conveyor belt mechanism is adopted to improve the convenience of loading or unloading magazine

- Defective foil will be transferred to the waste bin automatically, preventing downtime and ensuring continuous automatic production

- The lightweight aluminum alloy maintenance doors are easy assembly and disassembly for maintenance purposes

- The design for low-tension foil pulling reduces foil stretching and deformation

- EPC compensates winding shift of the foil

- Foil Cutting System by CCD Alignment ensures precise cutting of the foil according to the pattern

- The lamination of foil is highly precise. The precision of lamination can be maintained within ±1mm, with CCD measuring accuracy after the lamination

- The special liner peeling design minimizes the usage of tape, significantly reducing the costs of consumables

Operation

Fully Automatic

Specifications

| Dimensions | 5400 × 2550 × 2600 mm ( L×W×H includes tricolored light ) |

|---|---|

| Weight | 4375 kg |

| AC Power | 220V single phase 50 / 60 Hz |

| Air Source | 6 ~ 8 bar |

Object Wafer and Ring

| PET Foil | 280 × 200~380 mm ( W × L ) |

|---|---|

| Core Range | Dia.: 3 & 6 inch; L: 500 & 700 mm |

| Carrier | 400 × 300 × 0.5~5 mm ( L × W × H ) |

| Tape Size (liner peeling) | Inner Dia.: 3 inch *Outer Dia.: 125 mm *W: 12~18 mm |

Features

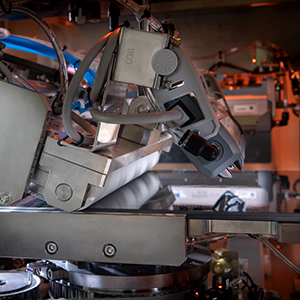

Aligner System

Two diagonally positioned vision lenses are adopted for optimal foil alignment.

Detection System for Number of Reject Mark

The large-field vision lens is adopted to automatically detects the number of reject marks on the foil.

Recognizing System of Cutting Position

The dual vision lenses are adopted to enhance overall cutting precision by automatically recognizing and calculating the foil cutting position.

Recognizing System of Foil Lamination

Equipped with two high-resolution vision lenses, it can calculate the accuracy of foil lamination to the carrier.

EPC System

It enhances the linear motion of the foil.

Barcode and QR Code Reader

Cassette barcode and carrier ID scanner.

Automatic

Fully automatic rapid production.

Replace Film Scrolls Rapidly

Support to replace film scrolls and waste film scrolls rapidly.

SEMI

SECS ∕ GEM

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.