Feature

- SECS ∕ GEM

- Suitable for single ∕ double-sided films

- Fully automatic mounting and laminating (suitable for mounting wafer + ceramic plate ∕ glass)

- The top and bottom plate of the hold-down mechanism are heated to deal with multiple types of film.

Advantages

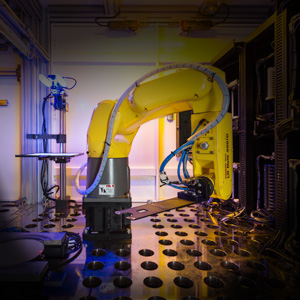

- Fully automatic rapid production with robot arm

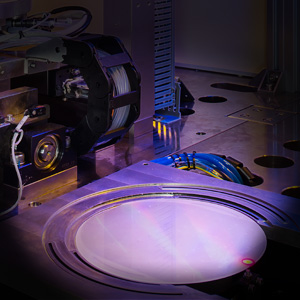

- Lamination in a vacuum environment reduces significantly the residual gases at the laminating interface.

- Loading ∕ Unloading cassette sufficiency

- IR lamp heating function

- Two screens for easy operations.

- Graphic presentation of important statistic data

- User-friendly operation for manual wafer placement

Operation

Take the 6” wafers out of the cassette using the robotic arm. Align the wafer and identify the top and bottom surfaces before placing the wafers on the attachment platform.

Step 1

- Move the attachment platform to the membrane application position. With the pressing roller and membrane clamp pick up the membrane and move the moving carrier to the cutting position.Rotate the cutter to cut the membrane. With the peeling tape, remove the release film from the 6” wafers. Move the moving carrier to the vacuum lamination position.

Step 2

- Take the wafer carriers out of the cassette with the robotic arm. Align the carriers and identify the top and bottom surface before placing the carriers on the attaching disc.Lower the vacuum laminating mechanism to the predefined position and start vacuuming with the vacuuming cover. Start the lamination of the 6” wafers and the carriers as soon as the predetermined vacuum value is reached.

Specifications

| Dimensions | 3320 mm × 1100 mm × 2400 mm ( W×D×H ) |

|---|---|

| Weight | 2500 kg |

| AC power | Working Voltage: 415 ( 3 phase ) ∕ 240 ( 1 phase ) Volt. (V)

Plant Safe Current: 60 A |

| Air supply | Air Pressure 0.8 MPa

Air Tube Diameter Ø 12 mm |

Object Wafer and Ring

| Wafer size | 6″ |

|---|---|

| Chip size | None |

| Laser cut depth | None |

| Flat ring size | – |

| Tape size | Width 180~250 mm × Length 100 M |

| Wafer carrier | 6″ ( Ø 150 mm )、6.5″ ( Ø 165 mm )、8″ ( Ø 200 mm ) |

Features

Vacuum

Lamination in a vacuum environment reduces significantly the residual gases at the laminating interface

IR Lamp

Optional IR lamp for heating depending on process needs

Automatic

Fully automatic rapid production

Adhesive

The adhesive membrane does the job for lamination

Quick Replacement

Quick replacement of membrane and waste material reels

Barcode Reader

For lamination, it can read barcode to record wafer information

Applied Evenly

The laminating pressure is applied evenly

Cut to Fit Shape

For double-sided lamination, the film is cut to fit the required shape at the wafer laminating station according to the outer diameter of the wafer

Aligner Identify

The combination of robotic arm and aligner helps identify the front and rear sides of the wafer and laminating film and flip them over if necessary and the work piece rotates to the correct laminating position automatically

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.