Feature

- CCD of detecting full ∕ broken wafer

- Top CCD

- SECS ∕ GEM

Patent

Top CCDCCD of Detecting Full ∕ Broken WaferPressing MechanismBreaking ModePatented Breaking Seat

Advantages

- CE-certified

- Changeable hammer strike forces

- SECS ∕ GEM

- Barcode for product identification

- Breaking of 8” wafer with 8” flat ring

- Optimized HMI for easy learning and use

- Additional safety devices for safer operations

- Multiple CCDs and light sources for different product needs

- PC ∕ PLC: user-friendly touch screen; advanced image processing system

- Advanced anti-static device is used to remove large range of electrostatic changes from the breaking process.

Operation

The wafer attached to Flat Ring is placed onto the table of the breaker from the cassette automatically. In the image system, the laser cutting line level is adjusted automatically, and the laser cutting traverse level is adjusted automatically. After the locations of Y-axis and cutter-axis are searched on the edge of the wafer, breaking (in X and Y directions) is performed according to the recipe of the work piece types. After breaking is complete, the operator unloads the work piece.

Specifications

| Dimensions | 1370 mm × 1260 mm × 2250 mm ( W×D×H ) |

|---|---|

| Weight | 950 kg |

| AC power | 1 Ø 220 V ∕ 4.5 A |

| Air supply | 5 Kgf ∕ cm2 ( 6 Ø Tube ) |

Object Wafer and Ring

| Wafer size | 2″~ 8″ |

|---|---|

| Chip size | 20 mils × 20 mils ~ 275 mils × 275 mils ( max. ) |

| Flat ring size | 8″ Flat Ring ( inner Ø 250 mm; outer 296 mm; t=1.0 ~ 1.3 mm ) |

Features

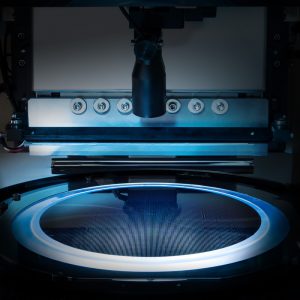

CCD of Detecting Full ∕ Broken Wafer

Automatic identification of intact/broken work piece and rapid search for wafer boundary for great reduction of splitting time

Y-Axis Aligns Automatically

set each cut or any cut to align once

θ-Axis Calibration and Y-Axis Alignment

set each cut or any cut to align once

Step Servo Motor for Key Mechanism

Double advantages of positioning compensation by servo motor and the stability of step motor

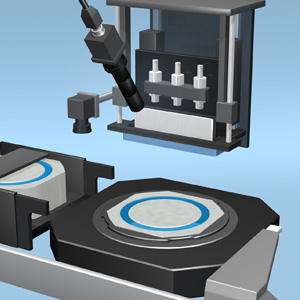

Patented Hold-Down Mechanism and Several Patented Breaking Modes

Wafers are held down to reduce wafer warping and improve production yield for breaking

Top CCD

Top CCD, recognition of ODR products

Vision Recognized

Non-cut detecting function, multiple non-breaking check functions

Search Edge of Wafer Automatically

Broken piece detection, search edge of wafer automatically and single X-axis alignment are provided for faster search

Adjust Level

Starting at auto breaking mode and adjusting the level have been double checked to make sure the level is correct

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.