Feature

- Process wafer expansion & Remount automatically

- CCD detects the outer diameter of wafer after expanding

- SECS ∕ GEM

Patent

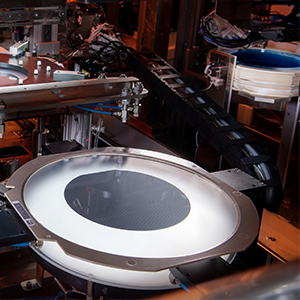

CCD detects wafer after expanding

Advantages

- Minimize tape consumption

- Cassette/ Frame barcode reader and tape RFID reader

- Provide PAUSE function in automatic mode to supply frames and change tapes.

Operation

- ➠Manually put the cassette with 8-inch frames attached wafers into the loading cassette, and an empty 6-inch cassette into the unloading cassette.

- ➠The 8-inch frame in the loading cassette is picked out by Arm to tuning module, and adjust X、Y、θ alignment.

- ➠After alignment, the 8-inch frame is moved to expansion module by Arm. The cutting mechanism in the expansion module is lifted up to cut off the original film.

- ➠After the 6-ich frame is mounted, Arm takes the 6-ich frame to expansion module. The 6-inch and 8-inch frames are compressed.

- ➠The 6-inch frame and the original film are turned over and transferred to the film detapping module by Arm to peel the original film.

- ➠The 6-inch frame is taken to the unloading cassette by Arm.

*Each station is operated by the exclusive arm that are different.

Specifications

| Dimensions | 4350 × 2170 × 2670 mm ( W×D×H ) |

|---|---|

| Weight | 4500 kg |

| AC power | 240V single phase, 50/60Hz |

| Air supply | Air Pressure 6~8 Kgf/cm² Air consumption 70 m³/h Air Tube Diameter Ø 12 mm |

Object Wafer and Ring

| Wafer size | 6″ (optional: 8″) |

|---|---|

| Ring Size | 6″ / 8″ |

| Tape size | 265 mm (W) × 100 M (L) for 6-inch frame 300 mm (W) × 100 M (L) for 8-inch frame |

Features

Automatic

Fully automatic rapid production

RFID Reader

Tape RFID reader

Barcode reader

Cassette / Frame barcode reader

Minimize Tape Consumption

Minimize (6-inch frame) 265 mm (W) ×230±5 mm (L) tape consumption to reduce operation cost.

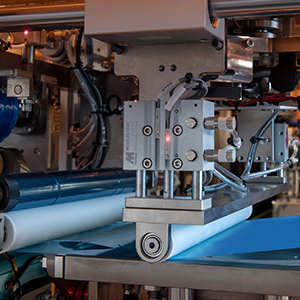

Adjustable Tape Tension

Provide optimum cutting conditions with adjustable tape tension.

Replace Film Scrolls Rapidly

Support to replace film scrolls and waste film scrolls rapidly.

Heat Expansion Station

Support to heat the wafer expansion station to 80℃.

CCD Inspection

CCD inspection checks the external diameter, and re-expand if does not separate enough.

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.