Feature

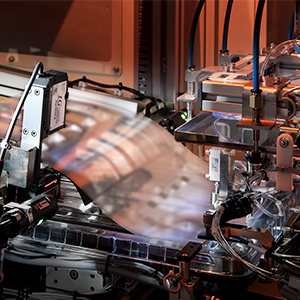

- Fully Automated Loading/Unloading and Transfer System

- Fully Automated Foil Detach Process

- Equip with Fully Automated Electrostatic Measurement

- The special configuration helps to completely eliminate static electricity generated during foil detaching

- The special air plate structure is adopted for separating foil

Patent

Stripping DeviceStacking Device

Advantages

- HEPA high efficiency air filtration for Class 1000 cleanroom environment

- The automatic conveyor belt mechanism is adopted to improve the convenience of loading or unloading magazine

- The lightweight aluminum alloy maintenance doors are easy assembly and disassembly for maintenance purposes

- The 15° low-angle separating foil can prevent foil stretching and deformation

- With a high-precision edge sensor, the alignment of the foil with the tray can be improved

- Picking up blister trays with a vacuum suction cup can prevent damage to the surfaces of blister trays

- The anti-static soft conveyor belt is adopted to prevent damage to the foil

- The non-contact foil detaching technology is adopted to prevent scratches on the foil

- A special error prevention Poka-Yoke mechanism is adopted to ensure correct tray placement

Operation

Fully Automatic

Specifications

| Dimensions | 3200 × 2104 × 2370 mm ( L×W×H includes tricolored light ) |

|---|---|

| Weight | 1845 kg |

| AC Power | 220V single phase 50/60Hz |

| Air Source | 0.6~0.7 Mpa |

Object Wafer and Ring

| PET Foil | 280 × 380 mm ( W×L ) |

|---|---|

| Carrier | 400 × 300 × 0.5~5 mm ( L×W×H ) |

Features

Barcode and QR Code Reader

Cassette barcode and carrier ID scanner.

Automatic

Fully automatic rapid production.

SEMI

SECS ∕ GEM

EPC

With a high-precision edge sensor, the alignment of the foil with the tray can be improved.

Aligner System

The mechanism alignment technology is adopted to carrier dimension variations due to tolerance changes.

Non-Contact Foil Detaching Technology

The foil from the carrier will be detached by utilizing the principle of blowing air plate.

Position Recognition System for FOIL

With a sensor, ensuring consistent positioning, the foil with the tray.

Stacking Mechanism

During operation, the system will stack trays with products to the bottom of other trays to reduce the surface contamination of the products in other layers.

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.