Feature

- UV LED light source, good uniformity, long life, low operating temperature, illumination monitoring

- Nitrogen chamber for low nitrogen consumption and good effect

- Supports RFID, SECS/GEM, overhead hoist transport (OHT) system

Advantages

- Nitrogen environment

- LED UV light source

- No preheating/warm-up required

- It contains no mercury and does not produce ozone which is harmful to humans

Operation

Step 1: Place the 12″ frame cassette on the carrier.

Step 2: The mapping sensor starts scanning the number of frames in the cassette and detects if double slot.

Step 3: Use gripper to remove the frame to a set position for frame alignment.

Step 4: Use the alternating arm (A) to move the first frame after alignment to the irradiation platform, while using the jaws to remove the second frame for alignment.

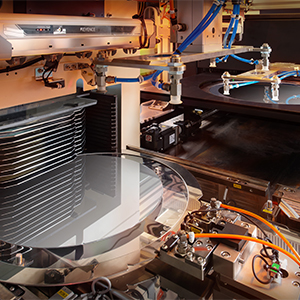

Step 5: Move the irradiation platform into the UV irradiation chamber and lower the N2 airflow disc to the irradiation platform for N2 blowing cycle, while using the handshaking arm (B) to pick up the second aligned frame on standby.

Step 6: Switch on the UV lamp which moves slowly from below the irradiation platform to irradiate the entire surface of the tape to cure it.

Step 7: Move the irradiation platform out of the irradiation chamber and use the alternating arm (A) to remove the first frame and move it to a set position, then use the alternating arm (B) to place the second frame on the irradiation platform for irradiation.

Step 8: Use the jaws to put the first irradiated frame back into the cassette and then take out the third frame.

Keep repeating Steps 3 to 8.

Specifications

| Dimensions | 1925 × 1445 × 1840 mm ( W×D×H ) exclude from tricolored light. |

|---|---|

| Weight | 1350 kg |

| AC power | 220 (1 phase) |

| Air supply | Air Pressure 0.5~0.7 MPa Air Tube Diameter Ø10 mm |

Object Wafer and Ring

| Wafer size | 12 inch |

|---|---|

| Chip size | – |

| Laser cut depth | – |

| Ring size | 12 inch |

| Label size | – |

Features

Cassette Loading

Single cassette operations.

OHT

Overhead hoist transport (OHT) system reservation.

Double Slot

Number of wafer scans, double slot judgement.

Great Efficiency

Twin sucker arms for alternate transport to reduce waiting time.

RFID

Cassette RFID reader.

Static Elimination

Static elimination device.

Signal Feedback

Digitization of each monitoring meter head and signal feedback.

Intensity Adjusted

The UV lamp intensity can be adjusted according to production requirements.

Monitoring

UV illumination monitoring, temperature monitoring.

Low Temperature

No thermal radiation, low temperature rise on the illuminated surface.

Uniform Illumination

Stable light output and uniform illumination.

SEMI

SECS / GEM / E84

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.