Feature

- The printed label sticker to be automatically adhered to the adhesive tape

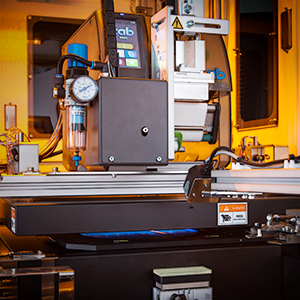

- The intensity of the UV light source and the speed of the ring frame during UV irradiation can be adjusted

Advantages

- Capable of monitoring the intensity of illumination

- Capable of monitoring the temperature

- Does not require preheating

- Less heat generated by the machine

- Does not include mercury and does not produce toxic material

- Low consumable costs

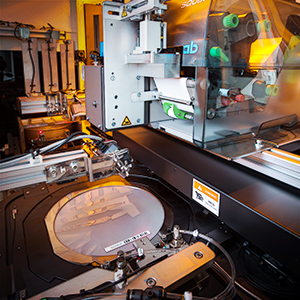

Operation

Identify the size of the loading cassette and indicate if it should be placed in a 8-inch ring fixture. → Guide rail auto switch corresponds to ring 8 “or 12”. → Robotic pickup arm moves the ring frame over to the guide rail. → Guide rail ring correction tuning. → The traveler/barcode information is picked by the reader and new label sticker with all the required information is printed out. → The claw arm takes the iron ring to the irradiation platform. → And label Sticker drops to attach label. → Ring Frame will be moved to the UV chamber for the irradiation and debonding process. → Ring frame will be moved back to the unloading cassette.

Specifications

| Dimensions | 1680 mm × 1350 mm × 2280 mm ( W×D×H ) |

|---|---|

| Weight | 850 kg |

| AC power | 1φ / 240 Volt.(V) |

| Air supply | AIR Size / pressure φ10 / 5~6 mm/Kg/cm2 N2 Size / pressure φ10 / 3~4 mm/Kg/cm2 |

Object Wafer and Ring

| Wafer size | 6″ / 8″ |

|---|---|

| Chip size | – |

| Laser cut depth | – |

| Ring size | 8″ / 12″ |

| Tape size | – |

| Label size | label width 20~116 mm / minimum label height 6 mm |

Features

Does not require preheating

Less heat generated by the machine

Low consumable costs

Capable of monitoring the intensity of illumination

Capable of monitoring the temperature

Does not include mercury

Does not produce toxic material.

*The information provided here is for reference only. The actual specifications of equipment depend on the equipment requested and delivered.